Brief description

The technology we used is from Germany. We can provide you top level machines with competitive price and perfect services. We are integrated with design, R&D, production, marketing, and after-sales services.

Rincian cepet

Papan Asal: China (Dharatan)

Jeneng: EMM

Model Number: DM-402

Layanan Sawise Sales: Engineers kasedhiya kanggo mesin jaban rangkah

Type: FIPFG formed in place foam gasket manufacturing

Strip width: Micro type: 2-8mm; Standard type: 5-30mm

Technology: Mixing head designed and manufactured in Germany

Dosing system: Barmag metering pump

Control system: Taiwan Syntec CNC system with hand controller

Driving system: Panasonic servo motor

Cleaning system: Water rinsing, built-in the mixing head.

Working speed: 0-12m/s, usually be 6-10m/s

Raw material: Polyurethane, PU, Silicon, other liquid material

Certifications: CE, ISO, RoHS, SGS, CQC, etc.

Deskripsi Produk

2 components EMM automatic PU foam sealing gasket making manufacturing machine

Mesin iki bisa nyampur loro jinis bahan mentahan bebarengan lan tuangake menyang posisi sing wis diatur, alur, jamur, utawa lumahing datar ing workpiece kanthi langsung. Liwat reaksi kimia, bahan baku cair mbentuk jalur sealing elastis sajrone detik. Ora ana titik gabungan utawa potong, saengga mbandhingake karo efek sealing liyane efeke luwih apik lan kanthi nggunakake maneh urip. Lan nalika proses pambentuk, permukaan jalur pelapisan dadi alus lan tanpa retakan, saengga efek sealing sing sampurna. Lan, amarga bisa nemplek ing workpiece kanthi alami lan tightly, ora ana gluing buruh needed, biaya ageng disimpen saka pegawe lan wektu, etc.

Peralatan sealing busa digunakake luwih akeh ing sealing lapangan kaya ngontrol lemari, lampu, kendaraan motor, industri mesin, dll. Iki bukti bocor, bukti minyak, bukti air, redaman, bukti kebisingan, lan penyegelan, dll. karo sertifikasi kaya UL / CE, MIL-STD-167, EN50298, lan liya-liyane.

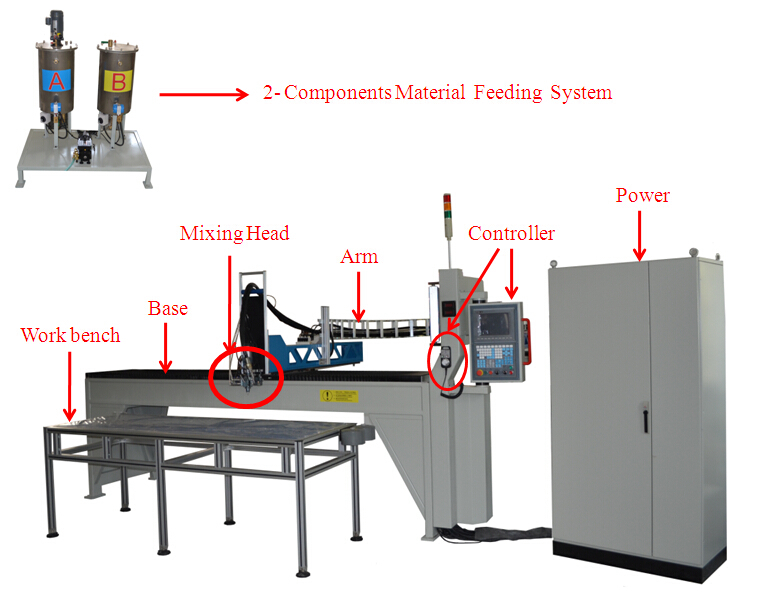

Gasket making machine Construction:

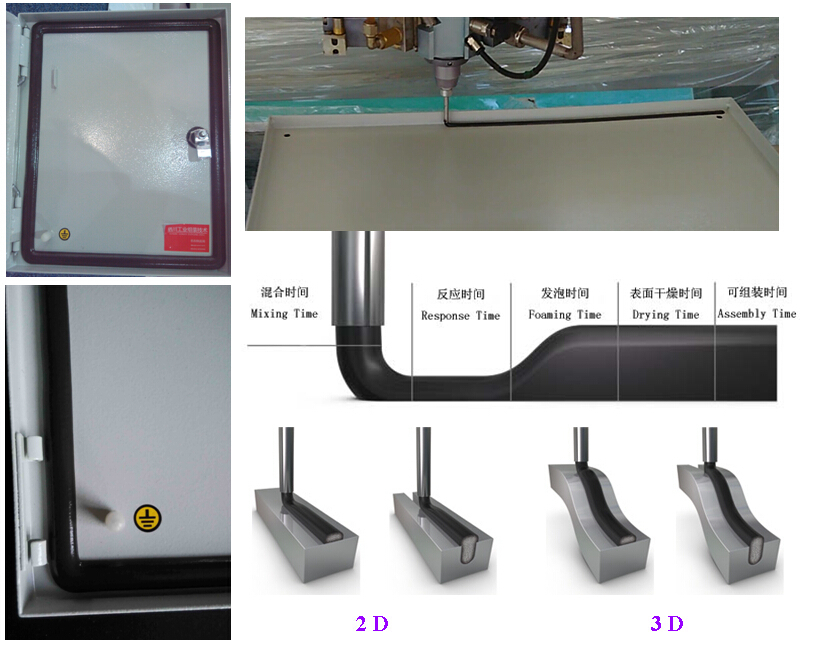

Gasket making machine Raw Material Reaction Principle:

Gasket making machine Main Parts

1. Mixing Head:

Water Rinsing & Modular Design

2/3 sirah nyampur komponèn karo sistem pembilasan banyu tekanan tinggi lan sistem pencampuran dinamis, kanggo nggunakake cairan kanggo bahan reaksi polimer dhuwur-viskip kanggo gasketing, gluing lan potting.

2. Sistem Operasi:

Sistem CNC saka SYNTEC, 180 derajat berputar bebas, Multi-basa pilihan, Nyimpen informasi sing kerep digunakake, Plus antarmuka USB lan program G-kode, Operasi Manual kanggo pilihan uga, Bisa dioperasi mung.

3. Barel Bahan Mentah:

Pindho stainless steel, suhu kontrol otomatis.

4. Work bench:

Aluminium alloy, kuwat lan tahan lama.

5. Sistem Sampel:

Pompa metering Barmag, Panasonic servo motor, Microscale gluing bisa diterapake.

6. Tangan Controller:

SYNTEC digawe, gampang kontrol, respon cepet lan anteng.

7. Sistem Driving:

Panasonic servo motor, nyediakake kanthi tetep, kanthi nggunakake urip dawa, bisa terus kerja nganti puluhan jam.

Our Gasket making Machine Equipment Advantage:

| Our Company, Jinjie | Some other companies | |

| Teknologi | From German, top level, mature and stable | R&D in China, Chinese level, in developing |

| Kepala Nyampur | Made in Germany (Germany manufacturing and processing technology, and quality) | Made in China, Chinese quality. |

| Mode Kerja | 2D or 3D for choice (could process special 3D patterns) | 2D only |

| Mode Kontrol | 8 axis linkage as a whole (1X+1Y+1Z+2Mixing+2Reserved, Could adjust & change to 3-components equipment or adding auto material feeding system according to needed.) | 3 axis + other control systems, need matching |

| Gluing Width (Standard type) | 5-30mm | 8-30mm |

| Gluing Width (Micro- type) | 2-8mm | 3-8mm |

| Baleni Ketepatan Positioning | +/-0.03mm | +/-0.05mm |

| Dosing | 0.5~5g/s | 1~4g/s |

| Continous working time | can keep working for a whole day (there is a special coating on the mixing head to prevent residual) | Frequently temporarily stop for cleaning residual |

| Processing capability of factory | machine shop belongs to ourselves, Jinjie | Processed by another company, then assembled in another place. |

| Offer | Very competitive | Higher |

Gasket making machine Standard type equipment specifications:

| Spesifikasi Teknis | Sawetara rincian liyane | |||

| Mechanical Arm | 6*3 m | Teknologi | Saka Jerman | |

| Workbench | 2.4*0.9 m | Kepala Nyampur | Saka Jerman | |

| Bahan Bench | 1.2*0.85 m | Operasi | Saka Taiwan Syntec, sistem CNC | |

| Nggawe Stroke | 2.4*1.2*0.25 m | Tangan Controller | Saka Taiwan Syntec | |

| Gluing Width | 5-30 mm | Motor | Panasonic Servo Motor | |

| Gluing Precision | 0.01 mm | Metering Pump | Saka Jerman, Barmag | |

| Nggawe kacepetan | 0-12 m / min | Reresik | Banyu Risining | |

| Max Speed | 30 m/min | Material Barel | Pindho stainless steel, suhu kontrol otomatis | |

| Baleni Ketepatan Positioning | +/- 0.03 mm | Mode Kontrol | 8 linkage sumbu, 1X+1Y+1Z+1mixing+2metering+2reserving | |

| Dosing | 0.5-5 g/s | Mode Kerja | 2D utawa 3D | |

| Filling Accuracy | 0.1 g/s | Werna utama | Silver abu-abu, waca gambar, utawa ireng, abang, dll. ing ngrembug. | |

| Nyampur Kacepetan | 0-3000 rad/min | Custom-made, OEM, ODM | OK, ora ana masalah. | |

| Nyampur Rasio | 1:10~10:1 Adjustable | Sertifikasi | CE, RoHS, ISO, lan liya-liyane. | |